Hot Surface Igniter

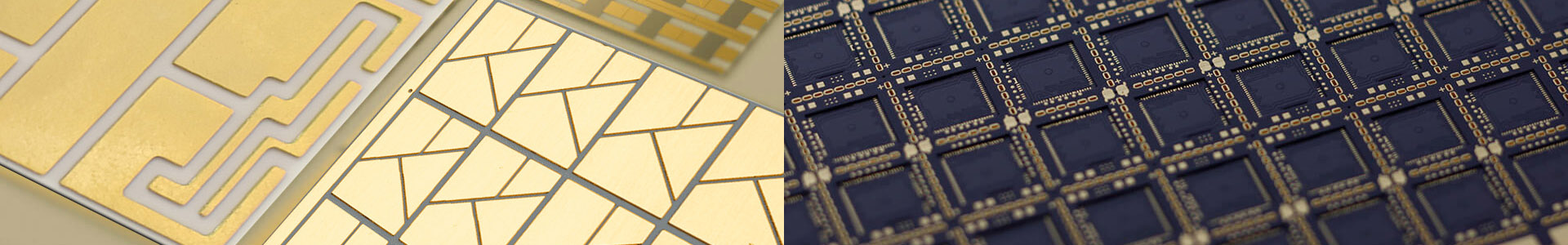

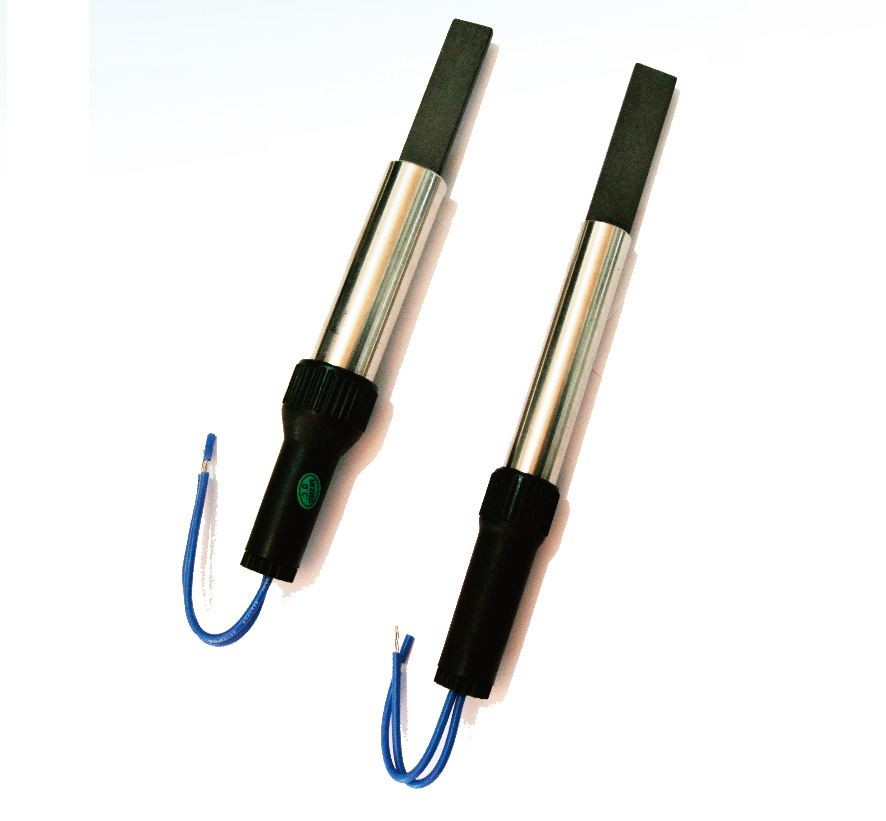

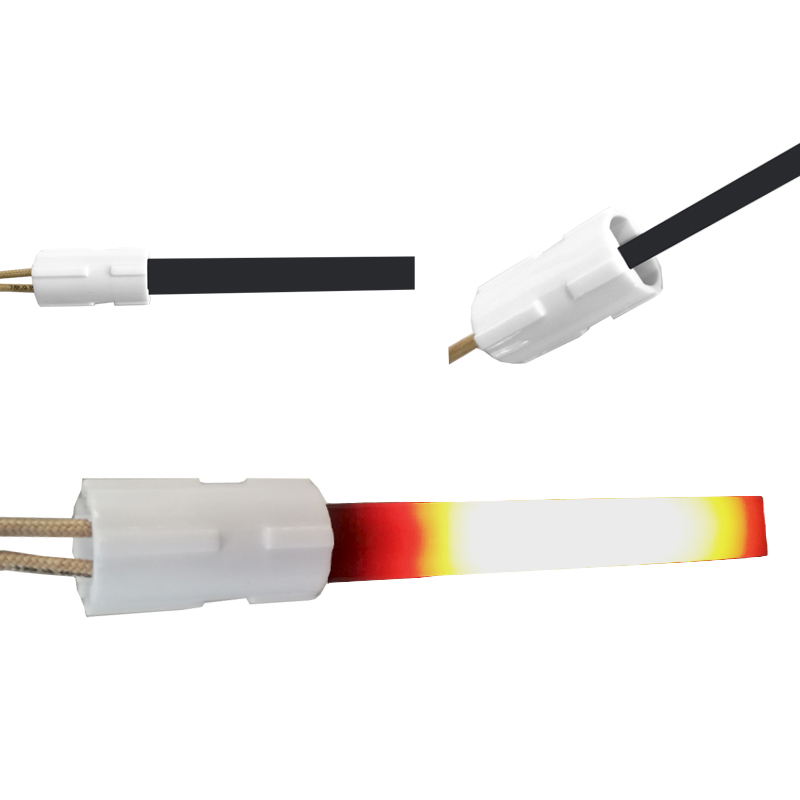

The Torbo® Hot surface igniter Application Made in China:Gas clothes dryer,gas ranges,gas oven,HVAC systems,gas grills,gas furnace,gas stove,gas boiler,gas burner. A hot surface igniter (HSI) is an ignition component commonly used in gas-fired appliances, such as furnaces, gas water heaters, and some gas stoves and ovens. Its primary function is to safely and efficiently ignite the gas in the combustion chamber, allowing the appliance to start and operate. Here are some key features and functions of a hot surface igniter:Ignition Method: Hot surface igniters work on the principle of electric resistance heating. They are made of a ceramic or silicon carbide material, which can withstand high temperatures. When an electric current passes through the igniter, it heats up rapidly, becoming red-hot.Safety: One of the main advantages of hot surface igniters is their safety. They do not use an open flame like a pilot light, which reduces the risk of gas leaks and unburned gas emissions.Efficiency: Hot surface igniters are highly efficient in igniting the gas because they reach very high temperatures quickly. This results in more reliable and consistent ignition.

Hot surface igniter Advantage: 1.Very long life,no breakage and no attenuation after 100000cycles of 30seconds on and 2minutes off

2.Big hot area,ensure 100% successful ignition

3.High efficiency,17seconds reach 1000℃ 4

.Stable thermal function,steady temperature 1100-1200℃,no attenuation and non aging.

5.High strength,toughness and hardness,anti-oxidation and anti-corrosion

- View as