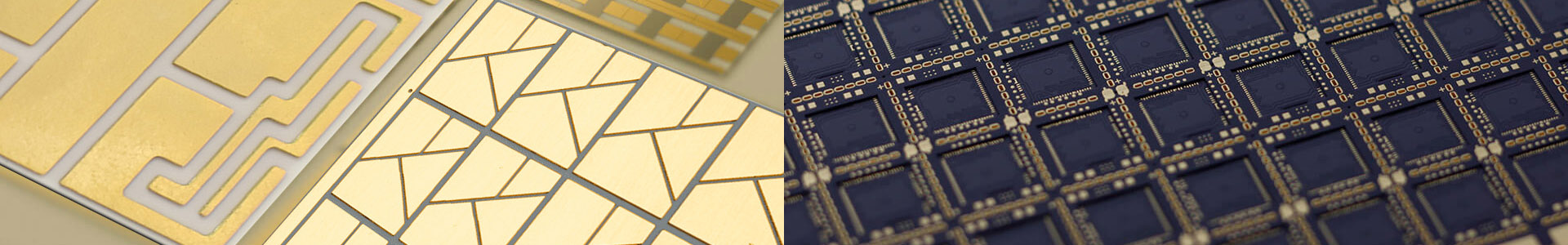

Silicon Nitride Ceramic Heat Component

Send Inquiry

Silicon Nitride Ceramic Heat Component

The maximum safe heat load of silicon nitride heater can reach 70 W/cm2. 1/3 size

of traditional electric heater will provide you open ended design possibility.

Smallest Size

Fast Heating Up

Long Serving Life

Silicon Nitride Ceramic Heat Component made of silicon nitride are normally rectangular in shape. Alloy wire is wrapped in dense silicon nitride ceramic body, where silicon nitride plays the role of heat transfer medium, dielectric medium as well as protect cover of alloy wire. With excellent thermal conductivity, insulation performance and comprehensive mechanical properties, the thickness of Torbos silicon nitride ceramic heat component is only 4 mm. The unmatched thermal expansion coefficient makes the scale crack and fall off on their own from the ceramic heater surface. The maximum safe heat load can reach 70 W/cm2, this makes this ceramic heat component only 1/3 in size compared with traditional electric heater. This extraordinary heat component is your reliable choice for you heat solution and will provide you open ended design possibility.

![]()

Application of Silicon Nitride Ceramic Heat Component

Instant Water Heater, module

Water Dispenser

Coffee Machine

Food processing equipment

Storage Water Heater

Vapor generator

Physical and Chemical Properties of Silicon Nitride

Density

Bulk Density: 3.2~3.3 g/cm3

Relative Density (%) : 99~100%

Mechanical Properties

Fracture Toughness: 5.0-8.0 MPa*m1/2

Bending Strength (RT) : ≥800 MPa

Bending Strength (HT) [1] : ≥600 MPa

Vickers Hardness [2] :15~20 GPa

Dielectric Properties

Relative Dielectric Constant: 6~7

Volume Resistivity: 1014 Ω*cm

Thermal Properties

Thermal Conductivity: 40~50 W/(m*K)

Thermal Expansion Coefficient : 3.0 x 10-6 /K

corrosion resistance

Acid Corrosion Resistance: Corrosion rate<10 g/m2∙h after 6 h in 5%

sulfuric acid boiling solution

Alkali Corrosion Resistance: Corrosion rate<0.6 g/m2∙h after 6 h in 30%

sodium hydroxide Boiling solution

Three point bending strength under 800 oC

The values is the test result under 10 kg load

Electrical Specifications

Voltage: AC110~380V~, 50/60 Hz, DC12V, 24V, 60V

Power:50~4000 W

Electric Insulation Strength: 2500 V/ 50 Hz,60 second no breakdown happens (Room temperature)

Leakage Current: ≤0.25 mA in working condition [1]; ≤10 mA if

break in water

Life Time: >5000 h

Power on/off cycle: 100,000 次/Times

Max. Heat Load: 70 W/cm2

Heating Medium: Water, acid/alkali solution, oil, organic liquid, gas, etc.

Although the leakage current is negligible, we still highly recommend you set the ground connection

This 10 mA is the safe limitation stated in IEC60335 (GB4706.1-2005)

The maximum surface heat load of a ceramic heat component depends on the property

of heat medium, heat transfer mechanism and working temperature (WT). For example the

surface heat load can be 70 W cm2 when heating water at WT under 80 oC

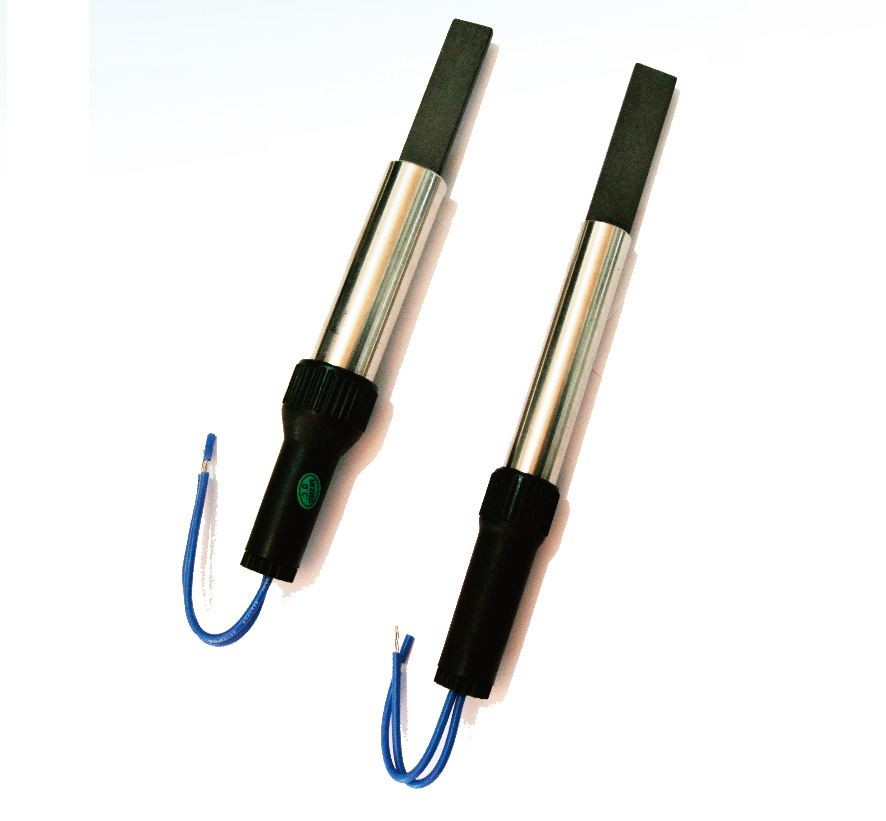

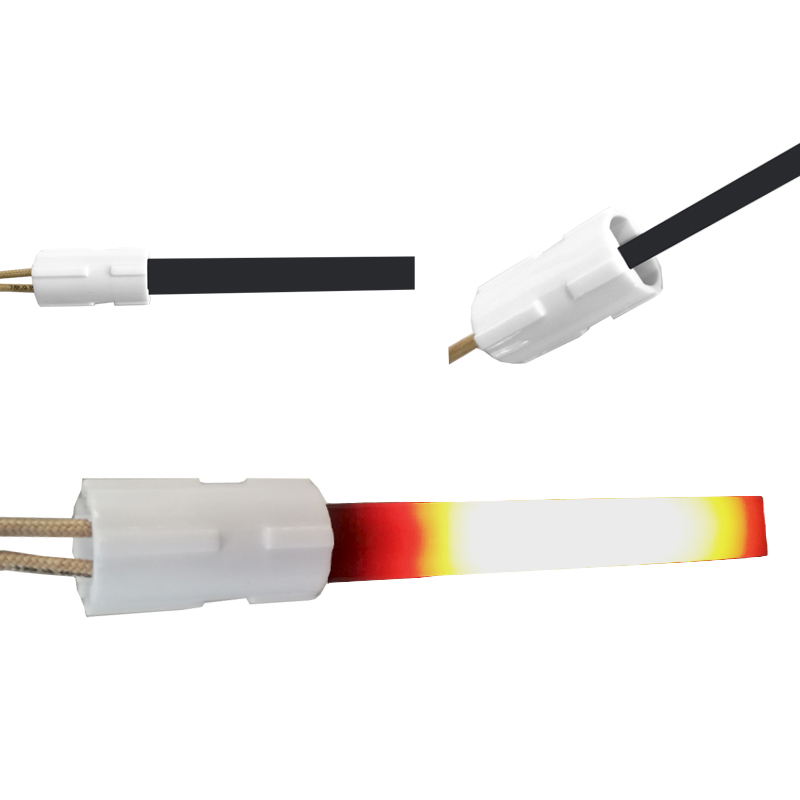

Structure of Silicon Nitride Ceramic Heat Component

![]()

Here listed the typical structure of TC series ceramic heat component

Model Type & Parameters

|

Model |

Dimension (mm) |

|

|

|

|

Power (W) |

|

|

LH |

WH |

DH |

LA | W |

|

|

TC-A |

90 | 17 | 4 | 25±2 | 200 |

600~2500 |

| TC-B | 75 | 30 | 4 |

25±2 |

200 |

400~3500 |

| TC-C | 57 | 17 | 4 | 25±2 | 200 |

800~1500 |

| TC-D | 95 | 24 | 4 | 25±2 | 200 |

400~3800 |

| TC-E | 100 | 17 | 4 | 25±2 | 200 | 400~2700 |

Dimension and power are customizable.