What is a ceramic glow plug?

2025-04-16

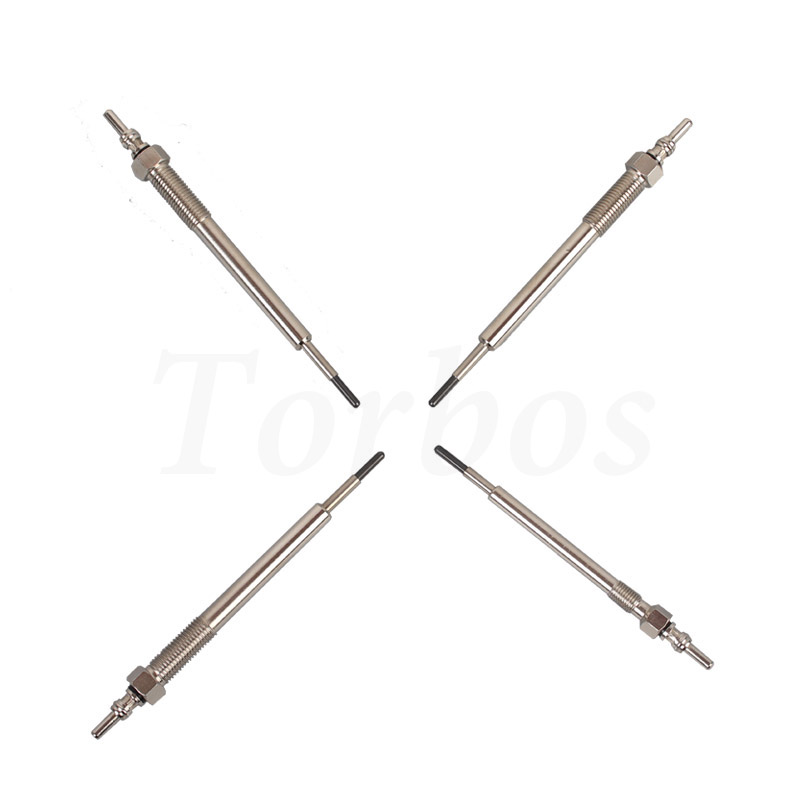

On cold winter days, cars often face challenges when starting, especially diesel engine vehicles. The importance of glow plugs is self-evident. Glow plugs, also known as electric glow plugs, are devices that help start the engine in low temperature environments.

The core function of the glow plug is to increase the internal temperature of the engine through electric heating before the engine starts, thereby reducing friction and wear during starting and improving the success rate of starting. In cold weather conditions, the viscosity of the engine oil increases due to the decrease in temperature, and the metal parts inside the engine shrink due to low temperature, which increases the difficulty of starting. The preheating of the glow plug can effectively alleviate these problems and make the engine start smoother.

In addition, glow plugs can also be divided into different types. According to the material, there are metal glow plugs and ceramic glow plugs. Different types of glow plugs have their own characteristics and are suitable for different engine requirements.

Ceramic glow plugs are significantly better than glow plugs made of other materials such as metal in terms of comprehensive performance, mainly reflected in fast response, resistance to extreme environments, long life and high efficiency and energy saving. Its core material (such as silicon nitride ceramic) can be heated to 900-1000℃ within 2-3 seconds, and can be stably started at a low temperature of -30℃, and the reliability of low-temperature start-up is far superior to that of traditional metal materials. Because ceramics have high melting points, low thermal expansion coefficients and excellent chemical stability, ceramic glow plugs can operate stably for a long time in high temperatures (such as 1150℃) and corrosive environments, and their service life can reach 5000 hours. Compared with metal materials, they are more resistant to wear and oxidation corrosion.

In addition, ceramic glow plugs optimize heating power through PTC automatic constant temperature technology, reduce energy loss in the cold start phase, and reduce pollutant emissions to meet higher environmental protection standards. In terms of structural design, ceramic preheating plugs use insulating packaging and temperature buffer areas to avoid the common short-circuit risks of metal materials and improve safety under high-temperature conditions.